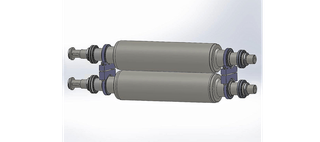

embossing rollers

reliability

from a single source

Our range covers embossing systems up to a total width of 4800 mm and a diameter of 600 mm.

Furthermore, our in-house engraving department will provide you with competent and individual advice on all questions relating to design and embossing.

Our production program comprises:

- Single rollers + embossing sleeves

- Steel / paper and steel / rubber roller sets

- Matched steel embossing rollers

- Pin-to-Flat embossing rollers

- Twin rollers

- Paper, rubber and plastic covers for counter-rolls

competence

becomes visible

Benefit from our patented solutions!

Compensation of Load Alternation

The compensation of load alternation device developed by UNIMATEC is a true milestone for embossing tissue products. By eliminating the bearing clearance in the system, the capacity of the rolls swinging is reduced to a minimum. This increases the service life of the rollers, and the uniformity of the layer adhesion is enhanced considerably. This is particularly important for the flat embossings of up to 0.2 mm as required today.

Quick Adjustment

The continuous optimization of the embossing process is one of our major areas of focus.

The UNIMATEC "pin-to-flat" roller sets with quick adjustment are one of the best examples for this.

This system, developed and patented by us, enables you to reproducibly change the embossing gap within seconds.

Multi Stage Nip Selector

The multi stage nip selector is a gap setting device with 4 preset gap dimensions.

This helps the machine operator to easily adjust the embossing gap to the material during production.

Please feel free to send us a detailed inquiry on the subject of embossing rollers.